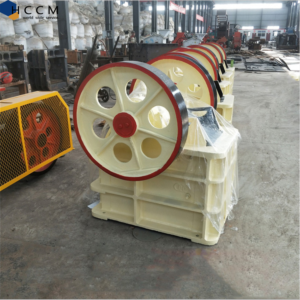

100Tph Stone Crusher Plant Stone Crushing Line

100Tph Stone Crusher Plant Stone Crushing Line

The crusher is used in the first process of crushing various ores and rocks and can process different ores in medium particle size simultaneously with compressive strength of 320MPa or less. Often combined with cone crusher, impact crusher, sand machine, etc., makes a complete set of sand and gravel production line. Widely used in fields such as mining, metallurgy, chemical industry, building materials, electricity, irrigation, and transportation.

1. Parts: When crusher mainly consists of frame, eccentric shaft, large belt pulley, flywheel, side guard, toggle plate, toggle plate rear seat, clearance adjustment screw, return spring, fixed jaw plate, movable jaw plate etc. Done

2. Principle of operation: When the crusher cross method is a rotating extraction type. During operation, the motor uses a belt and pulley to move the movable shaft up and down through the eccentric shaft. As the movable bangra increases, the angle between the toggle plate and the movable bangra increases, the movable jawbone plate reaches the fixed jaw plate, and the material passes through the two bengals. Obtained by squeezing, rugging and grinding between multiple crossing plates. As the movable brace descends, the angle between the toggle plate and the movable brace decreases, the movable jaws release the fixed jaw plate by the action of the pull rod and spring, and the material is crushed by the action of gravity. The bottom of the jaw cavity. It can be discharged independently from the discharge port. The constant rotation of the motor regularly crushes and pulls out the movable bungee, making it feel a great product.

| Place of Origin | Henan province, China |

|---|---|

| Brand Name | HCCM |

| Certification | CE ISO BV SGS |

| Model Number | PE500*750 |

| Minimum Order Quantity | 1 set |

| Price | 16500 USD/set |

| Packaging Details | China standard package |

| Delivery Time | 7-10 days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 50 sets per month |

| Model | Size of Feed Opening (mm) | Max.Feeding Size(mm) | Adjustable Sizeof Discharge Opening (mm) | Capacity (t/h) | Power (kw) | Weight (t) | Dimension (L×W×H)mm |

| PE1500×1800 | 1500×1800 | ≤1200 | 210- 360 | 520- 1100 | 280 | 132 | 7460×6235×4249 |

| PE1200×1500 | 1200×1500 | ≤1020 | 150- 300 | 400- 800 | 160-220 | 100.9 | 6380×5310×3710 |

| PE1000×1200 | 1000×1200 | ≤850 | 200- 300 | 280- 560 | 110-160 | 69 | 5350×4280×3050 |

| PE900×1200 | 900×1200 | ≤750 | 95- 165 | 220- 450 | 110-132 | 58 | 3800×3166×3045 |

| PE750×1060 | 750×1060 | ≤630 | 80- 140 | 110- 320 | 90-110 | 29 | 2655×2302×3110 |

| PE600×900 | 600×900 | ≤480 | 65- 160 | 90- 180 | 55-75 | 17 | 2290×2206×2370 |

| PE500×750 | 500×750 | ≤425 | 50- 100 | 40- 110 | 45-55 | 12 | 2035×1921×2000 |

| PE400×600 | 400×600 | ≤350 | 40- 100 | 15- 60 | 30-37 | 7 | 1700×1732×1653 |

| PE250×400 | 400×250 | ≤200 | 20- 50 | 5- 20 | 15 | 3 | 1430×1310×1340 |

Feature:

1. Unique jaw structure, sealing guarantee, extended bearing life. The unique flywheel design effectively reduces vibration and keeps the machine running more smoothly.

2. The gasket type outlet adjustment device has a wide adjustment range, is reliable and convenient, and improves the flexibility of the device.

3. Deep crossing cavity and no dead zone improves supply capacity and output. High crushing rate and uniform product size. New oil circuit design and use of support oil pumps make operation and maintenance easier and more efficient.

4. Adopting integral casting and new assembly technology, it fits perfectly in the frame and increases the radial force.

High jaw crossing rate, uniform production size, simple structure, reliable operation, easy maintenance and low operating cost.

When Crusher Operating Principle: The crushing method is a circular extraction type. During operation, the motor rotates the eccentric shaft to rotate the mill, and the movable rotator moves the material closer and farther away from certain jaws to periodically squeeze, rub and polish the material. When crushed, the material changes from large to small and falls off slowly until discharged from the outlet. The continuous rotation of the motor regularly crushes and discharges the movable crusher, achieving large output.

Other machinery

30tph Jaw crusher plant deliver to clients

HZS90 RMC Batching Plant PLD2400 Batching Machine

- Product List

- Concrete batching plant

- dry mortar plant

- asphalt mixing plant

- block making machine

- concrete mixer and pump

- self-loading concrete mixer truck

- cement silo

- concrete mixer truck

- concrete boom pump

- Crusher plant

- Other hot products

- Stationary Eco-Friendly Concrete Brick Machine Block Machine Manufacturer

- Professional Mini Excavator Manufacturer Small & Compact Excavators

- Hydraulic Block Making Machine, Vibration Press Brick Machine

- Wall Putty Ceramic Tile Adhesive Machine Dry Mortar Machines Ceramic Tile Adhesive Making Machine

- Customized Automatic Concrete Hollow Block Molding Machine

- Concrete Batching Mixer Vertical Shaft Planetary Concrete Mixer With Lift

- Customized Three Bins Concrete Batching Plant

- 50M3/H Stationary Planetary Concrete Batching Plant

- 4cbm Self Loading Concrete Mixer Truck for Self Mobile Concrete Mixer

- Factory Directly JS500 JS750 JS1000 Forced Double Shaft Concrete Mixers