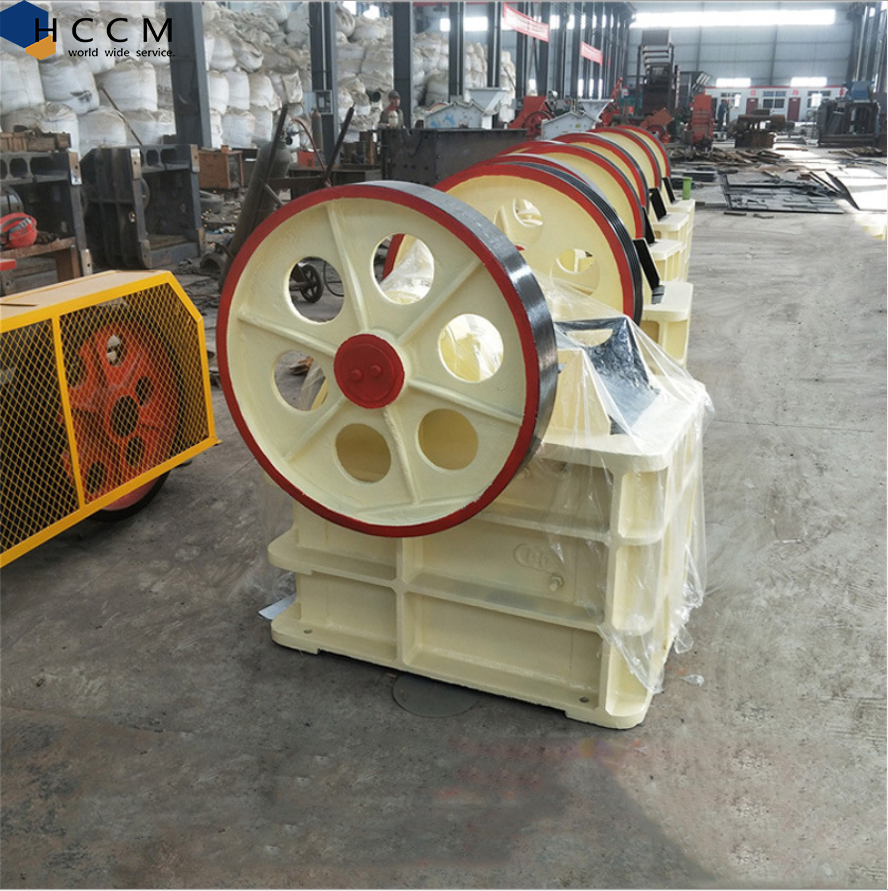

Low price jaw crusher

Low price Jaw Crusher

| Type:Jaw crusher | Input Size:Up to 900mm |

| Processed Materials: limestone, granite, basalt, andesite, quartz, silica, gypsum, volcanic rock, marble, river stone, gravel, pebble, pozzolana, Iron ore, copper ore, gold ore, manganese ore, etc. |

Applications: Mining, metallurgy, construction, highway, railroad, and water conservancy, etc. |

Jaw crushers are often used as primary crushers or the first step in the rock crushing process. They are usually shredded by compression. The rock falls between two hard pieces of metal, then one moves inward toward the rock, and the rock is crushed because its breaking point is lower than the opposite piece of metal.

The movement of the jaw crusher is achieved by using a fulcrum at one end of the “pivot jaw” and an eccentric movement at the other end.

Jaw crusher feature

1. The crushing ratio is high, and the particle size distribution of the finished product is uniform.

2. The discharge port of the jaw crusher can be reliably adjusted in a wide range by filling the middle layer to meet various requirements of customers.

3. The lubrication system is safe and reliable, and the maintenance is simple and convenient.

4. Simple structure, reliable performance and low maintenance cost.

5. Low dust and low noise.

Jaw crusher work guidelines

The motor transmits power through the belt, and drives the movable jaw to move intermittently to the fixed jaw through the eccentric shaft. The angle between the toggle plate and the movable jaw plate increases with the movement of the movable jaw. The movable jaw thus moves towards the fixed jaw. Something was crushed. As the movable jaw plate moves downward, the angle between the toggle plate and the movable jaw plate decreases, the movable jaw plate moves from the fixed jaw plate through the pull rod and the spring, and finally the crushed material is discharged from the outlet.

Jaw crusher Specifications

| Model | Feed opening (mm) | Max. Feeding Size (mm) | Adjustable Discharge opening (mm) | Capacity (t/h) | Motor Power (kW) | Overall Dimensions (mm) | Weight (t) |

| PE250×400 | 250X400 | 200 | 20-60 | 5-20 | 15(20) | 1150×1275×1240 | 2.8 |

| PE250x1000 | 250X1000 | 210 | 15-50 | 15-50 | 30(40) | 2790x2670x1380 | 6.5 |

| PE400×600 | 400X600 | 350 | 40-100 | 15-60 | 30(40) | 1700×1732×1653 | 6.5 |

| PE500×750 | 500X750 | 425 | 50-100 | 50-100 | 55(75) | 2035×1921×2000 | 10.3 |

| PE600×900 | 600X900 | 500 | 65-160 | 60-130 | 75(100) | 2290×2206×2370 | 16 |

| PE750×1060 | 750X1060 | 630 | 80-140 | 110-250 | 110(150) | 2620×2302×3110 | 27 |

| PE900×1200 | 900X1200 | 750 | 100-200 | 160-380 | 130(175) | 3789×2826×3025 | 46.5 |

| PE1000×1200 | 1000X1200 | 850 | 200-300 | 315-550 | 130(175) | 3889×2826×3025 | 56 |

| PE1200×1500 | 1200X1500 | 1000 | 150-350 | 400-800 | 200(270) | 4930X3148X3560 | 88 |

Other machinery :

100 Ton Cement Silo With collector For Grain / Fly Ash / Bulk Material Storage

Portable concrete batching plant -HCCM

- Product List

- Concrete batching plant

- dry mortar plant

- asphalt mixing plant

- block making machine

- concrete mixer and pump

- self-loading concrete mixer truck

- cement silo

- concrete mixer truck

- concrete boom pump

- Crusher plant

- Other hot products

- Stationary Eco-Friendly Concrete Brick Machine Block Machine Manufacturer

- Professional Mini Excavator Manufacturer Small & Compact Excavators

- Hydraulic Block Making Machine, Vibration Press Brick Machine

- Wall Putty Ceramic Tile Adhesive Machine Dry Mortar Machines Ceramic Tile Adhesive Making Machine

- Customized Automatic Concrete Hollow Block Molding Machine

- Concrete Batching Mixer Vertical Shaft Planetary Concrete Mixer With Lift

- Customized Three Bins Concrete Batching Plant

- 50M3/H Stationary Planetary Concrete Batching Plant

- 4cbm Self Loading Concrete Mixer Truck for Self Mobile Concrete Mixer

- Factory Directly JS500 JS750 JS1000 Forced Double Shaft Concrete Mixers